Mining operations require structural systems capable of supporting intense mechanical, geotechnical, and environmental loads. Retaining walls, MSE systems, precast tunnels, and engineered arches must sustain conditions such as heavy haul truck traffic, dynamic vibrations, chemical exposure, extreme temperatures, and blast‑related forces. Geoquest develops these structural components using sustainable, high‑performance materials engineered for predictable performance under severe mining conditions.

Mining‑grade retaining walls and arches may be designed for:

- Extreme vertical and lateral loads

- Seismic vibration and dynamic loading

- Impact forces from heavy equipment

- Thermal cycling and abrasive environmental exposure

- Fire and explosion resistance

These conditions define the load and durability specifications required for every geotechnical structure on a mining site.

Integrated Structural Design for Mining Facilities

Mining sites operate on interconnected infrastructure—haul roads, tunnels, crusher pits, bridges, storage bunkers, and process facilities. Each structure must perform reliably under continuous heavy loading. Our engineering teams design mining‑grade systems focused on long‑term durability, controlled deformation behavior, and consistent construction performance.

Primary Applications Supported

- Site infrastructure

- Haul roads

- Bridges and rail crossings

- Tunnels and reclaim systems

- Sloped and slotted walls

- Storage and drawdown structures

- Earth-covered bunkers

- Support for machinery, facilities, and processing operations

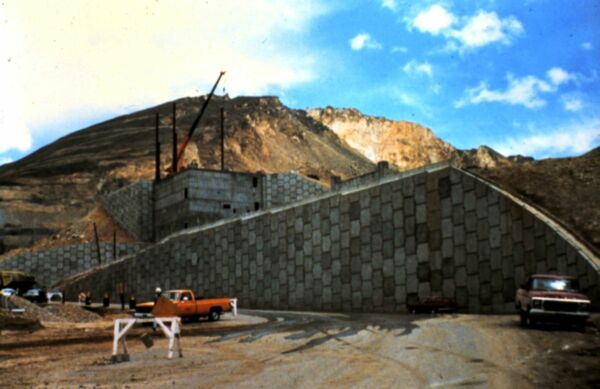

MSE Dump Walls for ROM Haul Truck Operations

Dump walls (also known as tip walls) are among the highest‑load retaining structures used in mining. These walls allow ROM trucks to tip ore into crusher pits. Geoquest has decades of experience designing Reinforced Earth® MSE dump walls for some of the world’s largest primary crushing facilities, including systems exceeding 120 feet in height. These walls support extreme live loads and maintain stability under severe climatic and operational conditions.

Engineering Components

Facing Components:

- Precast concrete panels

- TerraTrel® welded wire mesh

Reinforcement Types:

- High-adherence steel strips

- Geosynthetic strips

The selection of facing type and reinforcement system is determined through geotechnical analysis, live‑load calculations, local environment conditions, and wall height requirements.

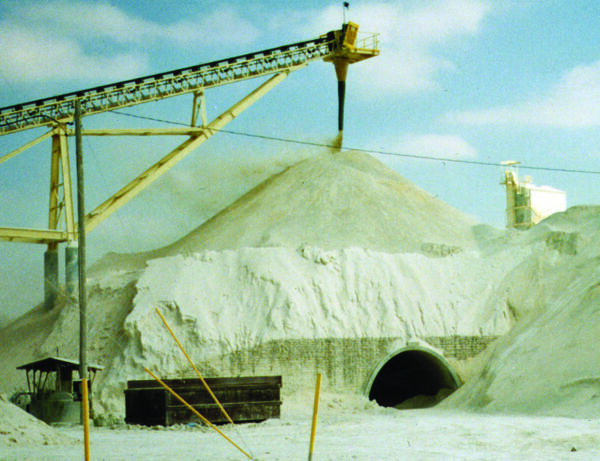

Precast Concrete Tunnels with TechSpan® Arches

TechSpan® precast concrete arches offer a modular, segmental solution for high‑capacity tunnels used throughout mining facilities. These arches are engineered to support the heaviest mining stockpiles and equipment loads.

Common Engineering Applications

- Reclaim conveyor tunnels

- Rail and vehicle tunnels

- Short-span bridges

- Shaft portals

- Rockfall sheds

- Pipeline covers and utility vaults

TechSpan® systems provide rapid installation, controlled tolerances, and predictable structural behavior.

Storage Slot Bunkers and V-Slot Systems

Mining operations rely on engineered storage structures for bulk material such as ore, coal, and mineral aggregates. These facilities utilize inclined Reinforced Earth® walls in linear, conical, or octagonal configurations.

These systems enable controlled material flow for reclaim operations and are engineered to match site‑specific drawdown characteristics.

Liquid Containment Structures and Pipeline Support

Mining operations require complex hydraulic and chemical containment systems. Geoquest engineers structures for:

- Reservoirs

- Settling basins

- Tailing ponds

- Froth and leaching ponds

- Hydro-transport pipelines

Elba Island LNG Terminal, Savannah, GA

Reinforced Access Roads for Heavy Haul Traffic

Mine access roads frequently traverse weak or variable soils. Heavy truck traffic can cause rutting and deformation if road layers are not properly reinforced.

Engineered Geogrid Composite Layers

Our geogrid‑reinforced roadway systems provide:

- Reduce aggregate requirements

- Improved load distribution

- Lower maintenance costs

- Mitigated rutting and deformation

These systems improve long‑term roadway resilience and operational efficiency.

Natural Risk Mitigation and Structural Upgrade Services

Mining operations must manage rockfall, avalanche, and slope instability risks. Geoquest provides engineered protection systems to minimize operational shutdowns and damage.

We also evaluate existing structures to determine:

- Load-increase capacity

- Upgrade or expansion feasibility

- Reuse or repair strategies

This extends asset life and reduces capital expenditure.

Conclusion

Mining infrastructure requires high‑capacity, long‑life structural systems engineered for extreme loading and environmental exposure. From MSE dump walls and precast arches to storage bunkers, access roads, and containment facilities, Geoquest delivers solutions designed for durability, rapid installation, and long‑term performance.

Geoquest’s engineering team works closely with owner’s and contractor’s engineering teams in developing solutions for complex needs. While our scope is limited to the design of our products to meet the owner’s specifications, our breadth of experience enables us to assist contractors and owners in delivering tailored, cost effective solutions for dozens of mining applications.